YCT-FT22 full automatic two nozzles tracking filling machine

Product Application:

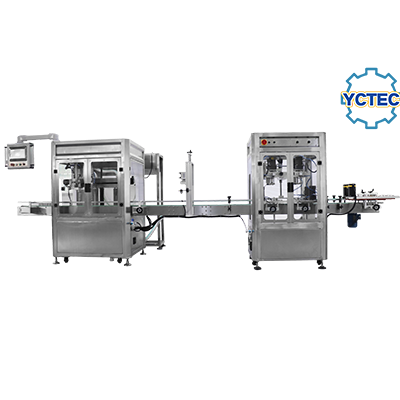

Machine photo:

YCT-FT22 full automatic two nozzles tracking filling machine

Scope of application:

◆ Applicable filling materials: honey, hand sanitizer, laundry detergent, shampoo, shower gel, and other materials. (Standard equipment uses 304 stainless steel for parts in contact with materials, please note if there is high-strength corrosive filling liquid)

◆ Applicable products: round bottle, flat bottle, square bottle, etc.

◆ Application industry: Widely used in cosmetics, daily chemical, petrochemical, and other industries.

◆ Application examples: hand sanitizer filling, laundry detergent filling, honey filling, filling, etc.

Working process:

*Core working principle: Start the machine, the sensor detects the passing of the product, and sends the signal back to the control system. After the system data calculation, when the bottle goes under the filling head, the bottle clamping cylinder of the filling mouth clamps the bottle Tracking filling is carried out after the mouth. After the filling is completed, the clamping cylinder is released, and the filling nozzle returns to the original point to complete a filling process; After the sensor detects the bottle, the capping mechanism knocks down the inner plug. After the inner plug is punched, the outer cap is manually placed on the bottle, and then enters the capping mechanism. After the sensor of the capping mechanism detects the bottle, the cap is screwed. The bottle clamping cylinder of the machine mechanism clamps the bottle, the cap locking cylinder and the cap screwing motor are started to screw the cap, all loosen after completion, the screwed bottle flows out, and it is completed!

*Operation process: start→bottle loading→detection→tracking filling→filling nozzle return to original position→put inner cap→press inner cap→put outer cap→clamp bottle→screw cap.

——Cycle on this way.

Technical parameters:

(The following are the technical parameters of standard models, other special functions can be customized).

◆ Applicable filling diameter (mm): ≥20mm

◆ Applicable filling range (ml): 500ml~5000ml

◆ Filling accuracy (ml): 1%

◆ Filling speed (pcs/h): 1800-2000pcs/h (2L)

◆ Weight (kg): about 360kg

◆ Frequency (HZ): 50HZ

◆ Voltage (V): AC220V

◆ Air pressure (MPa): 0.4-0.6MPa

◆ Power (W): 6.48KW

◆ Machine sizes (mm) (L*W*H): 5325*1829*1048mm

Features:

◆ Simple operation, convenient debugging, fool-like machine, easy to use;

◆ The filling system, lifting system and tracking system are all controlled by servo motors with high precision; the guardrails are controlled by stepping motors.

◆ It is not necessary to use tools to replace products of different specifications. The size of the product is all controlled and adjusted on the touch screen, and each product only needs to adjust the formula parameters for the first time. After the parameters are saved, it is necessary to produce this product later. There will be no more machine debugging. When changing products, just take out the specifications of the required products on the touch screen formula. After taking them out, the equipment will automatically switch and debug to the required product specifications, and then it can be produced. There is no need for manual debugging, and it can save 10 group recipe;

◆ The filling head is controlled separately, and the two filling systems are separated;

◆ The filling speed and filling volume can be directly input on the display screen, and the filling can be done without adjusting the mechanical parts;

◆ It adopts three-speed filling or two-speed filling, and the three-stage speed and filling volume can be adjusted to prevent the liquid from splashing out when it is full;

◆ Intelligent control, automatic photoelectric tracking, no bottle no filling;

◆ There is a clamping mechanism at the back end of the conveying machine; it can be connected to the back end and used for transition of the back end conveying line;

◆ High speed, widely used in industries;

◆ The main materials of the equipment are stainless steel and high-grade aluminum alloy, which conform to the GMP production standard. The overall structure is firm and beautiful.

For more detailed technical information and related labeling videos of this equipment, please contact us.

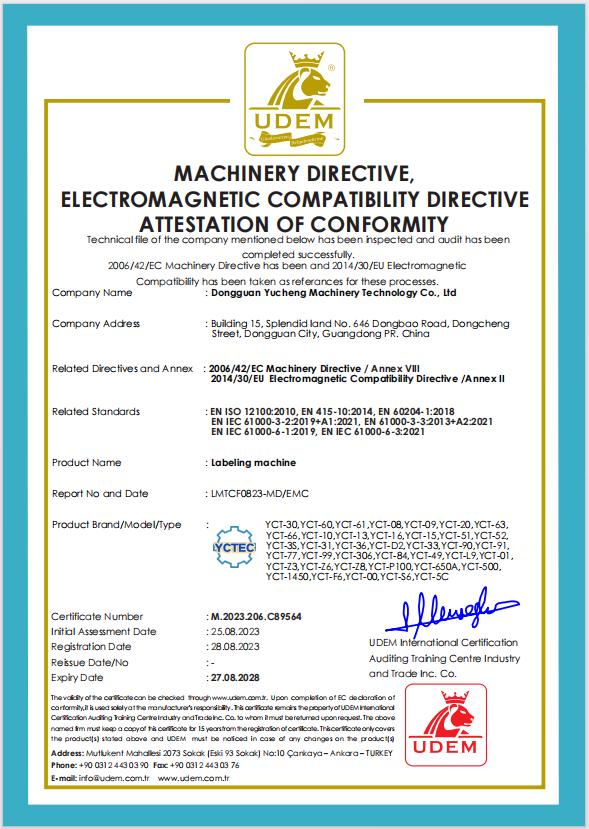

Certificate:

Video:

We have been deeply inivolved in the field of full

automatic packing equiments for more than 20 years.

We insist on making high-quality products, insisting on

making every product well, and providing customers

with better solutions, to bring safe, reliable and cost-

effective packaging machines and service to our

customers.

Yucheng Machinery

Yucheng Machinery