YCT-F06 Full automatic Six nozzle pisiton filling machine

Product Application:

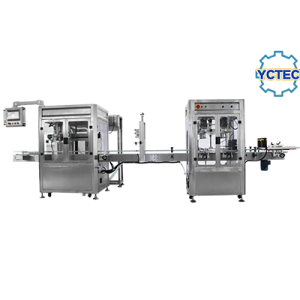

Machine photo:

Scope of application:

◆ Applicable filling materials: alcohol, antifreeze, glass water, essential oil, milk, soy sauce, camellia oil, honey, seasoning, honey, hand sanitizer, shampoo and other material liquids. (Standard equipment uses 304 stainless steel for parts in contact with materials, please note if there is high-strength corrosive filling liquid)

◆ Applicable products: round bottle, flat bottle, square bottle, etc.

◆ Application industry: Widely used in cosmetics, daily chemical, medicine, food and other industries.

◆ Application examples: alcohol filling, milk filling, honey filling, delicacy filling, tea oil filling, glass water filling, etc.

Working process:

*Core working principle: Start the machine, the front knife extends out, the sensor detects the passing of the product, and sends a signal back to the control system. When the control system receives the signals of 6 bottles, the back knife blocks the bottles behind, and the bottle mouth is fixed The mechanism blocks the bottle mouth, the material receiving cylinder is recovered, the filling lifting cylinder is lowered to fill, the lifting cylinder is raised after the filling volume is completed, the bottle mouth fixing cylinder is reset, and then the material receiving cylinder is stretched and reset, and the front stop knife is recovered , the filled bottles flow out from the conveyor belt to complete the filling.

*Operation process: Start→Extend the front knife→Bottle loading→Photoelectric detection of several bottles→Enough bottles→Extend the back knife→Position the bottle mouth→Retract the receiving tray→Down the filling cylinder→Filling→Complete filling Loading → lifting cylinder rises to the right position → bottle mouth positioning and reset → material receiving tray reset → front knife retracted → filled bottle sent out

——Cycle on this way.

Technical parameters:

(The following are for standard machine, more functions can be customized).

Filling capacity (ML) 100-1000ml

Production speed (BPM) 20-50 bottles/minute

Filling accuracy (ml) 1%

Applicable filling diameter (mm) ≥12mm

Applicable conveyor length: 40mm~140mm

conveyor width: 40mm~114mm

Bottle Height: 100mm~400mm

Power supply (VAC) 380V/220V

Motor power (KW) 3.0

Air consumption (MPa) 0.4-0.6MPa

Machine sizes: (L*W*H) 3023 × 1132 × 2497mm

Weight (KG): about 650kg

Features:

a: Touch screen operation interface

b: Eight up and down movement filling, effectively prevent foam

c: Filling accuracy can reach ±1%

d: The filling cylinder is treated and ground with hard chrome, the unique filling valve design, no dripping

e: With no bottle, no canning, automatic feeding function of the silo

f: Design different positioning devices according to the actual situation of the bottle

g: The equipment is easy to clean, can be folded and assembled without tools, and can also be cleaned online or sterilized at high temperature

h: PLC programmable control, using domestic well-known brands

i: Pneumatic components adopt Taiwan AirTAC

j: The material contact of equipment adopts SUS304 stainless steel

k: Equipped with a glass protective cover that meets hygiene and safety standards

l: Ensure particle-free filling

Advantages:

◆ The operation is simple, the machine is easy to operate, easy to use, and easy to debug. To change products of different specifications, you only need to adjust the width of the conveying guardrail and the distance between the filling heads according to the bottle type, and set the filling volume on the touch screen.

◆ Servo motor double-speed filling function is adopted, first fast and then slow, to prevent liquid from splashing out;

◆ The filling speed and filling volume can be directly input on the display screen, and the filling can be completed without adjusting the mechanical parts.

◆ Intelligent control, automatic photoelectric tracking, no bottle no filling, no filling if there are less than 6 bottles in the filling mechanism, and automatic filling cleaning pipe and air exhaust.

◆ The main materials of the equipment are stainless steel and high-grade aluminum alloy, which conform to the GMP production standard. The overall structure is firm and beautiful.

For more detailed technical information and related labeling videos of this equipment, please contact us.

Certificate:

Video:

We have been deeply inivolved in the field of full

automatic packing equiments for more than 20 years.

We insist on making high-quality products, insisting on

making every product well, and providing customers

with better solutions, to bring safe, reliable and cost-

effective packaging machines and service to our

customers.

Yucheng Machinery

Yucheng Machinery