Customer Case:

Product Application:

Basic Use:

The shrinking machine are widely used in various bottle types of fruit juice, tea drinks, dairy products, purified water, condiments, beer, sports drinks, cosmetic and other industries. It can achieve wrap around labeling, from top to bottom, for bottle neck labeling, etc.

Machine description:

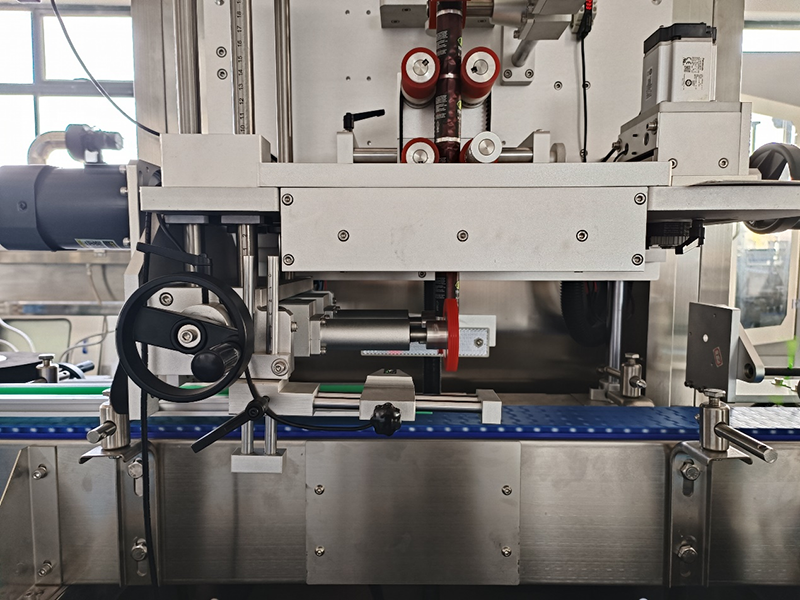

(1)The shrinking machine adopts photoelectric signal sensing, and the PLC processor converts the photoelectric signal to give mechanical instructions to the servo motors and drive components of the equipment, and cooperates to complete the label delivery of the material tray, the label moves up and down on the guide column, and the cutter head is cut and brushed Actions, such as swiping tags in the next round.

(2) After the bottle sensor senses that the material is transported on the conveyor belt, the PLC starts to process the signal and issue a work order within 1 second, and the equipment consists of a bottle group, a tray group, a rack group, a drive group, The bottle-carrying group, the brush-down group, the brush group and other components cooperate to complete the action of putting the label or transparent film on the material.

(3)The main body of the whole machine is made of 304# stainless steel, which is corrosion-resistant and does not rust, and strictly complies with food safety standards. The parts in contact with the sleeve label materials are non-toxic and free from harmful substance pollution.

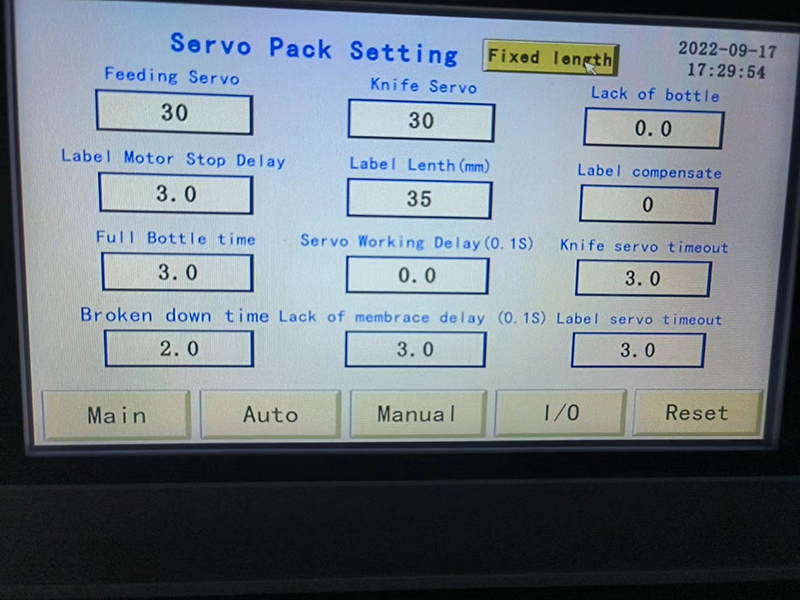

(4) It adopts a complete set of imported electrical equipment, which is controlled by Japan's Mitsubishi PLC, Kunlun Tongtai touch screen soft keyboard operation control, equipped with Japan's Panasonic photoelectric, France's Schneider servo motor, France's Schneider servo driver, the quality of the equipment is excellent and stable reliable.

(5) For standard machines, the corresponding central guide pillars are made according to different material sizes and bottle sizes. After replacing the guide pillars and the label film for sleeve labels, one machine can be compatible with multiple sizes. Material sleeve packaging. In the case of excessive material size difference, in addition to replacing the corresponding center guide post and label film, it is also necessary to replace the cutter head for label cutting.

(6) According to the design of the label film, it can be divided into ordinary photoelectric recognition transparency section cut mark, color code photoelectric fixed point recognition cut mark, and fully transparent unprinted film fixed-length cut mark.

(7) When using materials in the compatible range for production, in addition to replacing the central guide column and label film, it is necessary to adjust the height of the machine, the front and rear positions of the photoelectric bottle according to the size of the material, etc., and special equipment is required for operation and use during equipment installation and commissioning For training, please be sure to pay attention to learning to achieve the purpose of proficient use of equipment.

(8) The shrinking machine can be equipped with steam shrinkage and electric heating shrinkage, which can be determined according to different product packaging requirements and site dry humidity requirements. The normal water and beverage industry adopts steam shrinkage, the label shrinkage is smoother and more beautiful, and the requirements for label material, color, and shrinkage rate are low. Electric shrinkage is suitable for products that need to be kept dry, such as glass bottles, metal products, powders, and biscuit products, but it has higher requirements for labels, such as lighter colors, higher shrinkage rates, and better materials.

(9) The technology of shrinking machine is very mature, while you should pay attention to the voltage fluctuation of the power grid when using it. If the local voltage is unstable, a voltage stabilizer should be installed on the site where the equipment is used to prevent the voltage fluctuation from causing the electrical precision of the labeling machine. damage.

Our Advantages:

(1) All the machines are equipped with German Siemens electric appliances or Japanese Panasonic electric appliances of the same level. PLC processing is more accurate and stable, with small sleeve label errors and high precision. After debugging, there will be no missing labels or sleeves.

(2) The equipment adopts 304# stainless steel frame structure, matched with high-quality aluminum parts, adopts NSK bearings from Japan, and GATES transmission belt from the United States.

(3) Dual-language operating system of sleeve labeling machine, Chinese and English interactive interface. Machine appearance and operating system language can be customized according to customer needs. Our equipment is exported to Southeast Asia, Myanmar, Vietnam, Cambodia, Thailand, Japan, South Korea, Russia, Nepal, Ethiopia and other countries.

(4) Since the establishment of our company, our machines have been sold to many cities in China and abroad. The technical quality has withstood the test of time and has been recognized by customers. Customized is welcome.

Technical Parameters:

| Mold | YCT—200 |

| Power(kw) | 220V 2.0kw |

| Speed(b/min) | 100-200/min |

| Applicable bottle diameter:(mm) | Φ38—Φ120mm |

| Label length(mm) | 30~220mm |

| Label thickness(mm) | 0.03~0.13mm |

| Inner paper tube diameter (mm) | 5”~10” adjust freely |

| Machine sizes(mm) | 2100L*900W*2000H |

| Weight(kg) | 280kg |

Post time: Jun-15-2023

Yucheng Machinery

Yucheng Machinery